Sharp Eco Vision

As the world becomes more reliant on technology each year, the technology industry must reduce its impact on the environment, conserve resources, and work to protect the planet.

Our vision is to be Net-Zero as a business by 2050

Based on the 1.5°C target, this reflects our aim to reduce our CO₂ & GHG emissions

We’ve pledged to accelerate our efforts to become carbon neutral in our business activities

The actions we’re taking today are to achieve our goals for a sustainable tomorrow

Our goals in action

From establishing a circular economy to eco-friendly designs, here is what we’re already doing to achieve our sustainable development goals.

Expanding renewable energy

As the world grapples with ongoing climate change challenges, many are already experiencing the power green energy can offer. We’re steadily reducing CO₂ emissions by switching to renewable power; in 2023 we installed rooftop solar panels at one of our China factories in an effort to reduce production-related emissions in our domestic and overseas production bases.

- In 2023 we generated 4.49 million kWh of electricity and purchased 14.58 million kWh of green power through the launch of new new photovoltaic (PV) systems at plants in Thailand and Indonesia.

- Our factories in China have been using renewable energy and power generation since January 2023, resulting in a 367 tonnes CO₂ reduction in the first three months. These facilities are expected to reduce greenhouse gas emissions by roughly 1,830 tonnes of CO₂ per year.

- We will continue installing solar power systems in plants and other sites to save energy.

- Going forward we are set to convert our company fleets to electric vehicles (EVs).

Achieving a circular economy

A circular economy means to reduce, repair and recycle in a closed loop. Every part of a product’s lifecycle has a knock-on impact on climate change – that’s why our sustainable development goals (SDGs) account for every stage of the process: from product design and purchasing of materials to production, transportation and product usage. Some of the ways this is already in practice includes:

- Our latest Multifunctional Printers (MFPs) have a 17% reduction in plastics used in packaging alone, with packaging for specific A4 models to have zero-plastic (styrofoam).

- Use of heat-dissipating metal in product designs for our digital signage displays and LED modules to enhance longevity and preserve heat-sensitive electronic components.

- Extending the life of products with low-power consumption, low-resource use, active use of recycled plastic, improved waste management, and reduced CO₂ footprint from our MFPs through remote engineer maintenance.

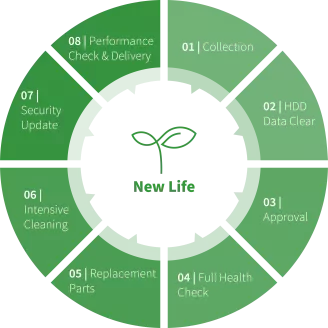

- Refurbishment programmes, such as the Prism Refurbishment Service for Digital Cinema Projectors and our New Life Printers programme.

- Decreasing volume of new water use: decreased by 9% compared to the previous fiscal year to 9.2 million m3. All water discharged through the production process is collected and reused through a closed loop recycling system. Thanks to this, we’re maintaining a recycling rate* of at least 60%.**

- Our final landfill disposal rate was 0.46%, achieving zero discharge to landfill*** on a global scale. Efforts are also made to reduce the volume of landfill waste by considering regulations governing packaging materials and batteries.

- Globally, our cumulative shipments of PV systems equate to 17 GW of power, translating to about 6 million tonnes of CO₂ avoided annually.

*Recycling rate = Amount recycled ÷ (amount of new water + amount recycled). **Sustainability Report 2024 (global.sharp). ***Sharp defines “zero discharge to landfill”, at its production sites, as a final landfill disposal rate of less than 0.5%. Final landfill disposal rate (%) = Amount of landfill disposal ÷ amount of waste, etc. generated × 100.

Managing a sustainable supply chain

We know that real, global change can only happen when everyone plays their part. We’ve outlined our medium and long-term goals and social initiatives for reduced CO₂ across the supply chain. Beyond just initiatives related to quality, price and the delivery of parts and materials, we include product safety, environmental protection, human rights and labour, and health and safety.

- Supplier expectations. We request suppliers to protect and conserve environments and conduct business operations in an environmentally conscious way.

- Human health and environment. For compliance of the EU REACH* regulation and under the Sharp Code of Conduct, we take proactive approach to compliance with laws and regulations to improve the protection of human health and the environment from the risks of chemical substances.

- Safety and security. We ensure the proper use and control of chemical substances in our business activities and are aiming to reduce overall consumption to protect people’s health, the natural environment and ecosystems**.

- Risk assessments. We periodically conduct supply chain CSR surveys in line with our Supply Chain CSR Deployment Guidebook, based on the RBA’s Validated Assessment Program***, to identify, reduce and combat risks.

- Transport. We’re actively reducing airfreight volume, reviewing shipping routes and switching to harbours located closer to final destinations. Sharp’s GHG emissions from international transport reduced by 20% between 2022 and 2023, from 138,000 tonnes to 112,000 tonnes CO2.****

*EU REACH Regulation | Sharp. **Sustainability Report 2024 (global.sharp). ***Validated Assessment Program. A VAP audit is a local audit performed by a third-party auditing service certified by the RBA. ****Sustainability Report 2024 (global.sharp)

Adopting sustainable practices across our products and solutions

Our development objectives are constantly revised each year to improve the environmental performance of our products. This factors in energy saving, resource conservation, recyclability and refurbishment, safe use and disposal, using recycled materials and designing products that have batteries with enhanced environmental consciousness. All of this relates to our Green Product (GP) Guidelines, which define the development and design criteria of all product design departments since fiscal 1998.

- Reducing energy consumption on standby modes by 40% for MFPs, along with low Typical Energy Consumption (TEC) value – up to 27% less than previous models.

- Our cloud-based print management solution, Synappx™ ensures the release and printing of documents in the most sustainable format.

- We use an infinitely recyclable metal chassis in our Large Format Displays, and these displays can be recycled repeatedly at a recycling rate of 97.4%, contributing to the circular economy.

Our carbon capture partnership

We view climate financing as a critical tool in scaling up our sustainability efforts. That’s why we have innovative climate financing initiatives in place to support projects beyond our value chain – fostering sustainability in the communities and environments we impact.

Working with our strategic climate partner Atmoz, we have invested in the Brandon Project operated by O.C.O Technology which uses an accelerated carbonation technology for carbon capture, repurposing waste into manufactured limestone. We are proud to support a facility that plays a key role in global efforts to mitigate climate change and promote environmental sustainability.

By incorporating climate financing into Sharp Eco Vision 2050, we can support our transition to Net Zero, facilitate innovation in green technologies, and contribute to climate resilience on a broader scale.

'Sharp is a major player'

Quocirca reports that Sharp is making progress on their sustainability vision, commitments, and deliverables, raising overall standards across the print industry.

Excerpt from Quocirca Sustainability Leaders Report 2024